Microstructure analysis

Metallurgical Image analysis software

Technical Specifications

“Copper Pro” is a modular quantitative image analysis software specific to steel industries. Simply select the appropriate analysis module and follow the intuitive guidance of built-in wizard. Incorporates industry standards including EN ISO 643, ASTM E-112, ASTM E – 930-92, ASTM 13 82-91. For analysis, sample is ground, polished and it necessary, etched using a suitable medium.

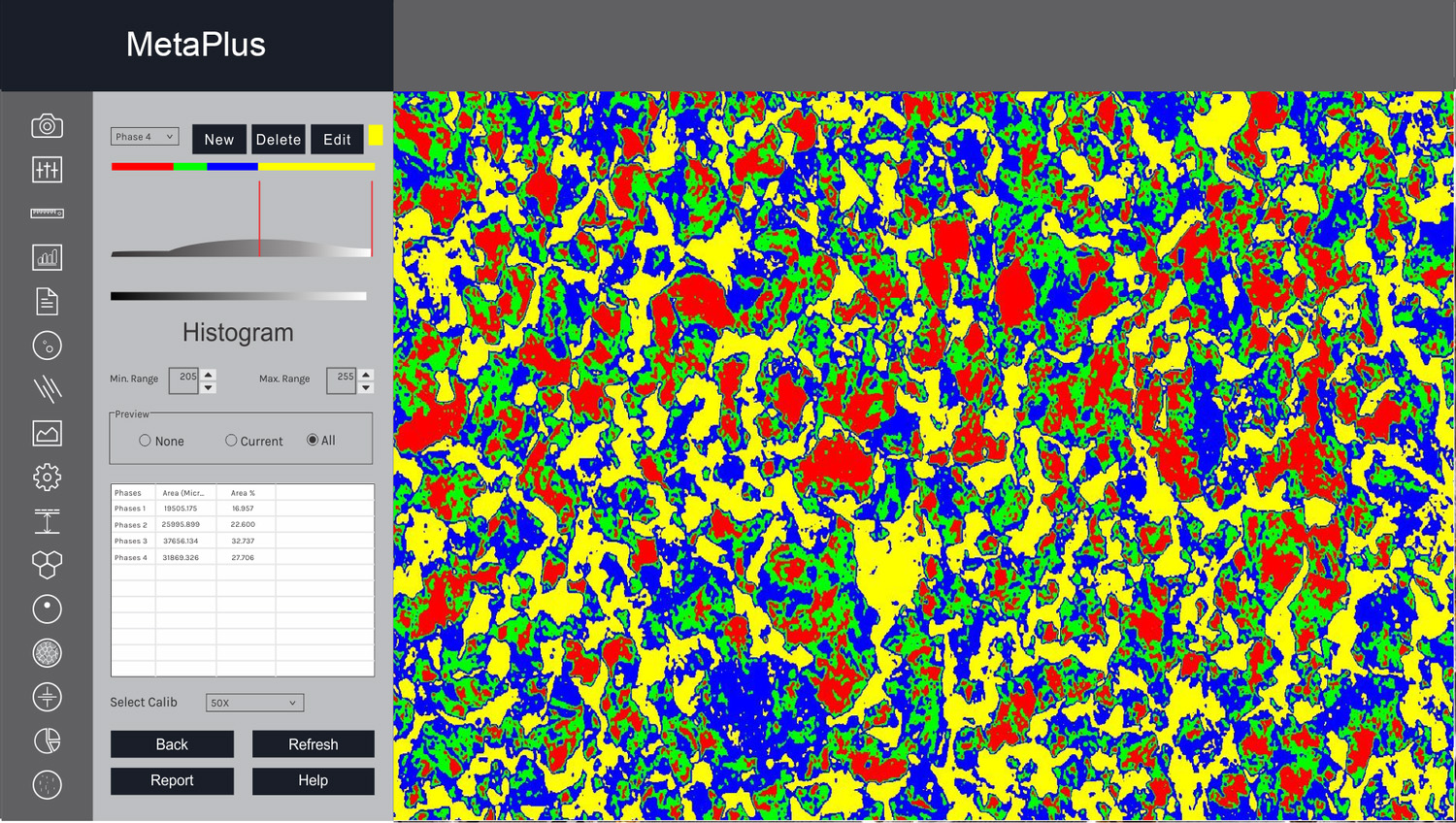

Segmentation is a method of image partitioning on the intensity / grayscale range of its

parts. Since a phase is detected and its area is estimated on the basis of its intensity /

grayscale, an option for delineating phases from the histogram is also provided. Multiple

phases are identify by colored overlays and can be simultaneously displayed in the same

field of view. The results and images displayed get stored in to distinguish the phases

prominently. Various filters like Despeckle, Smoothing etc can be used before doing

the phase.

A histogram for gray scale images is created once you open the Segmentation Module.

The X-axis represents intensity scale between 0-255. The Y-axis represents number of

pixels in the image. analysis. the industrial standard automatically.

HISTOGRAM: Phase allows the user to designate up to ten different threshold settings

to identify material phases and name each of these phases. The color between two lines

signifies a particular phase.

INTENSITY: The Gray Intensity range of the current phase gets display continuously in the

dialogue box.

SELECTED PHASE: This property enable the user to know the percentage area of a specific

range of intensity just by clicking the mouse. All previous operations have to be deleted

and Preview should be on None.

Standar Nilai

Tim kami berupaya membuat nilai tambah untuk proses manufaktur dan riset pelanggan kami. Melalui produk dan solusi teknis, kami mencari cara agar dapat memecahkan masalah berbagai aplikasi.